European standard customized & Automatic Z purlin roll forming machine with ISO quality system | ZHONGYUAN

European standard customized & Automatic Z purlin roll forming machine with ISO quality system | ZHONGYUAN

| Categories | Purlin Roll Forming Machine |

|---|---|

| Update Time | Apr 3,2025 |

Automatic Z Purlin Forming Machine

Automatic Z Purlin Forming Machine video,you can see more clearly.

| Technical data of Automatic Z Purlin Forming Machine | |

|---|---|

| Suitable Material | Cold-rolled steel strip and heat-treated galvanized steel strip |

| Thickness of raw material | 1.5-3.2mm (235-345Mpa) |

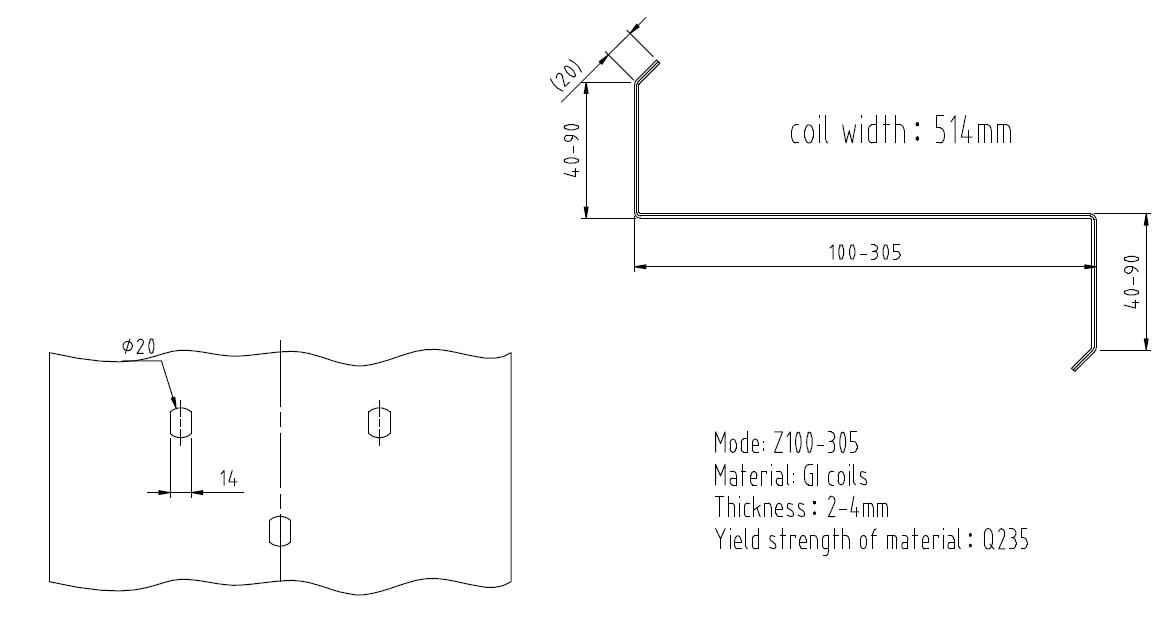

| Size of C purlin | 100-305mm adjustable (special size available) |

| Material of roller | Cr12 mould steel being quenched treatment,HRC58-60 |

| Material of cutter blade& punching die | Cr12 mould steel with quenched treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Power Requirement | Main motor power: 4X4 Kw(Depend on final design) |

| Hydraulic station power: 5.5Kw (Depend on final design) | |

| Diameter of shaft for rollers | 82mm |

| Controlling system | Mitsubishi PLC & converter |

| Quantity of rollers | about 15 stations for main rollers |

| Weight of machine | About 22000KGS |

| Size of machine | About 17.5mX2.1mx1.6m |

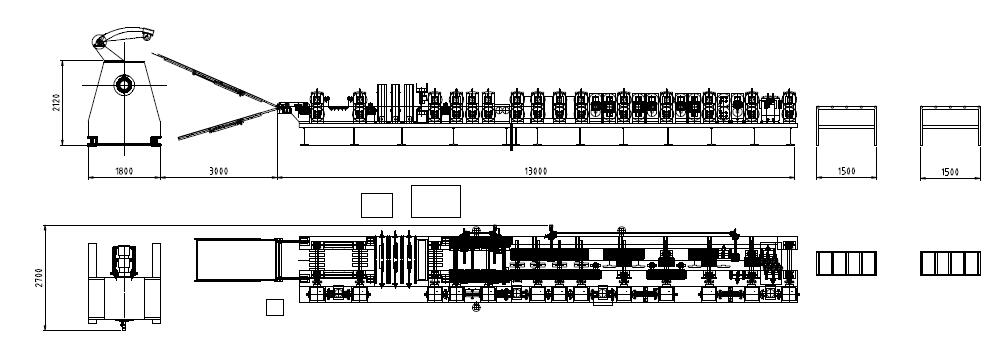

Layout drawing of Automatic Z Purlin Forming Machine

Gearbox transmission system

Gearbox transmission system moves the line to ensure machine strong enough to run raw material thickness 3.0mm

Automatic adjusting to do different sizes of Z purlin

Change size of purlin automatically. People key in and then the control system adjusts the different sizes automatically. Just push the button and the rollers will automatically adjust the required sizes without being adjusted by people.

One machine can do following different size, automatic adjustment. Special sizes of purlin can be designed in our company.

Produce Showing:

Our Roll Forming Machine’s advantages

1.Anti-rust roller: Cr12 mould steel being quenched treatment,HRC58-60, CNC machine tooled to increase rollers precision.

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifetime services for our machines.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content