European standard customized R101 Metal Cladding Roll Forming Machine manufacturer with ISO quality system | ZHONGYUAN

European standard customized R101 Metal Cladding Roll Forming Machine manufacturer with ISO quality system | ZHONGYUAN

| Categories | Metal Sheet Roll Forming Machines |

|---|---|

| Update Time | Apr 2,2025 |

Metal Cladding R101 Roll Forming Machine

Metal Cladding Roll Forming Machine video,you can see more clearly.

| Technical data of Metal Cladding Roll Forming Machine | |

|---|---|

| Suitable material | Q235 color steel sheet;0.3-0.7mm |

| Forming speed | about 20-25m/min |

| Power Requirement | Main motor power: 7.5 Kw(Depend on final design) |

| Hydraulic station power: 2.2Kw(Depend on final design) | |

| Material of forming rollers | No.45 steel, plated with chrome on surface |

| Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 9500KGS |

| Machine’s size | about 15m×1.8m× 1.5m (Depend on final design) |

| Shipping | 1x40GP container can load one machine |

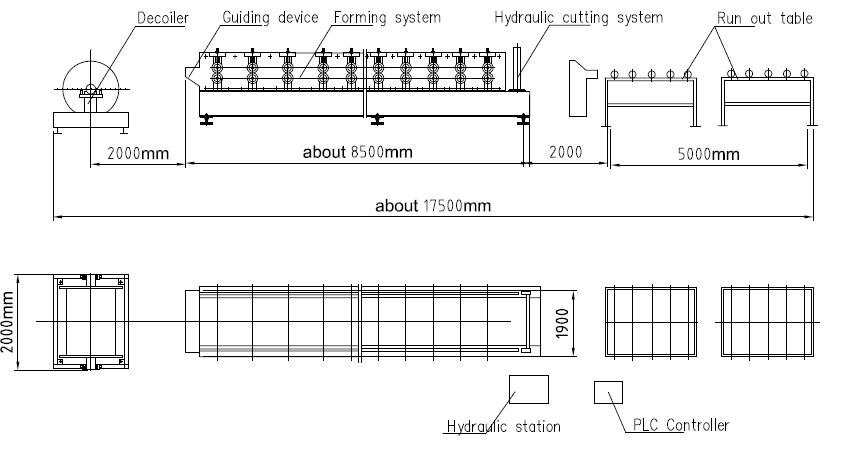

Layout drawing of Metal Cladding R101 Roll Forming Machine

Forming System

Bearings inside rollers:

Bearings inside the forming rollers to allow machine run with less loading, so that machine rollers not easy to be damaged to prolong machine life. More important, machine can get more precise sheet because of bearing designing.

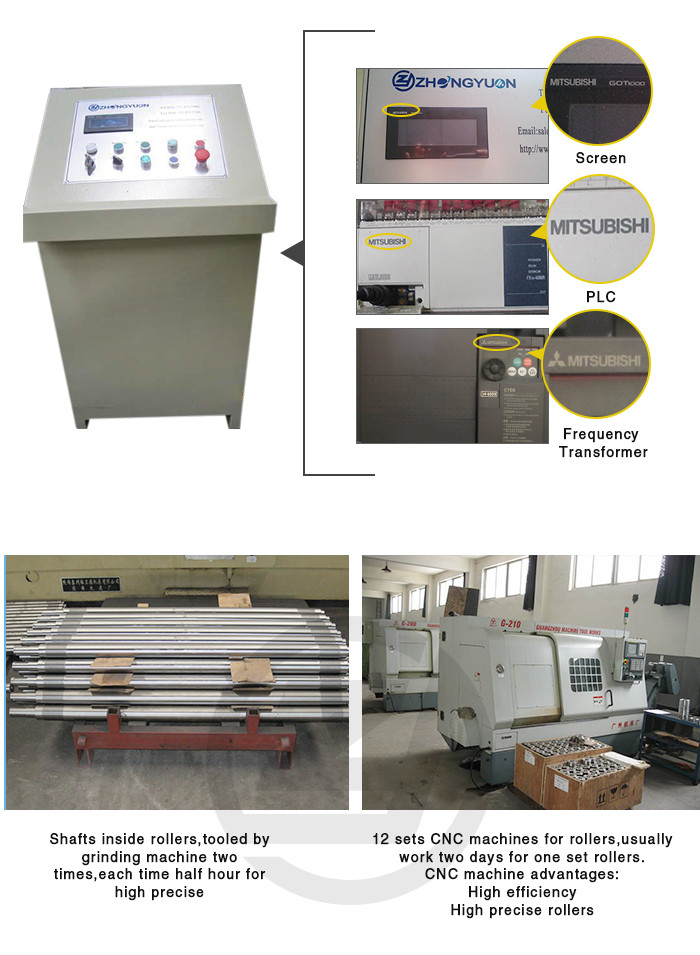

Machine shafts for rollers

1. Shaft material is No.45 steel with diameter 72mm, strong and durable.

2. Shafts are processed for three times from rough machining to grinder machining, to ensure the precision of final product.

Controller

once you set quantity and length of product,machine will produce product automatically.

Our R101 Metal Roll Forming Machine’s advantages

1.Forming speed: 20-25m per minute or 30-35m per minute . at least get 9600m per day. (based on one shift working 8 hour)

2. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .

3.Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

4. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

5. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

6. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

7. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifetime services for our machines.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content