Standing Seam Roll Forming Machines

Introduction: Overview of Standing Seam Roofing

Introduction: Overview of Standing Seam Roofing

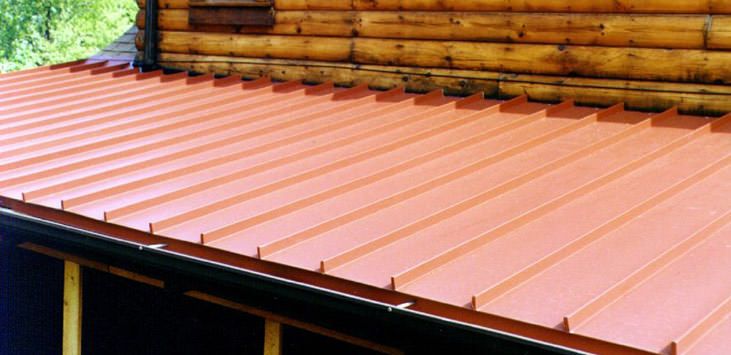

Standing seam roofing is a popular choice for both residential and commercial buildings due to its durability, aesthetics, and ease of installation. This type of roofing involves metal panels that are joined together with raised seams, providing a sleek and modern appearance. The seams are typically raised above the level of the roofing panel, which helps to improve water runoff and reduce the risk of leaks.

Product Listings: Machine Specifications

Product Listings: Machine Specifications

Standing Seam Roll Forming Machine

| Model | SSRF-100 |

|---|---|

| Material | Galvanized steel, Aluminum, Copper |

| Speed | 10-15 meters/minute |

| Width | 300-600mm adjustable |

| Thickness | 0.3-0.8mm |

| Power | 7.5kW |

| Features | Automated controls, precision cutting, and easy operation |

Standing Seam Panel Machine

| Model | SSPM-200 |

|---|---|

| Material | Galvanized steel, Zinc, Aluminum |

| Speed | 12-18 meters/minute |

| Width | 250-550mm adjustable |

| Thickness | 0.4-0.9mm |

| Power | 8kW |

| Features | High accuracy, versatile design, and robust construction |

Standing Seam Metal Roof Machine for Sale

Benefits: Durability, Aesthetics

Benefits: Durability, Aesthetics

Durability

Standing seam roofing systems are known for their longevity and resistance to harsh weather conditions. The use of high-quality metals such as galvanized steel, aluminum, and copper ensures that the roofing can withstand extreme temperatures, wind, and precipitation.

Aesthetics

The sleek, modern look of standing seam metal roofs adds a contemporary touch to any building. The clean lines and smooth finish of the panels provide an attractive appearance that can enhance the overall curb appeal of the property.

Installation Guide: How to Install Standing Seam Panels

Installation Guide: How to Install Standing Seam Panels

- Preparation: Measure the roof area and cut the panels to the required length.

- Layout: Position the first panel at the edge of the roof, ensuring it is straight and secure.

- Seaming: Use the standing seam roll former for sale to create the raised seams on each panel.

- Fastening: Secure the panels to the roof deck using appropriate fasteners and clips.

- Finishing: Apply any necessary sealants and trim to complete the installation.

FAQs: Common Questions About Standing Seam Machines

FAQs: Common Questions About Standing Seam Machines

Q: What materials can be used with a standing seam roll forming machine?

A: These machines are compatible with various metals including galvanized steel, aluminum, copper, zinc, and stainless steel.

Q: How do I maintain my standing seam metal roofing machines for sale?

A: Regular maintenance involves cleaning the machine, checking for wear and tear, and ensuring all components are functioning correctly.

Q: Are there different models of standing seam metal roof machine for sale?

A: Yes, there are various models available, each designed to accommodate different materials, widths, and thicknesses.

Q: Can I adjust the width of the panels produced by the standing seam panel machine?

A: Yes, most models allow for adjustable widths to suit different roofing requirements.

Q: Is it difficult to operate a standing seam roll former for sale?

A: These machines are designed to be user-friendly, with automated controls and precision cutting features to simplify the operation process.